History

Are you familiar with the story of Adhemar Ferreira da Silva? He is the only Brazilian to have won two consecutive Olympic championships in a single event, the triple jump. He rose to worldwide fame in the 1950s by making jumps of more than 16 meters – which some had said at that point was humanly impossible.

Adhemar left the world stunned by winning his second gold medal in a row and breaking the triple jump record in the first Olympics held in the southern hemisphere, in Melbourne, Australia in 1956.

It may seem strange, but the Brazilian automotive industry and Adhemer share a great deal in common. First there is the year: ANFAVEA, the Brazilian Association of Automotive Vehicle Manufacturers was also created in 1956, the year in which Adhemer broke the record. However, the similarities extend beyond the coinciding dates.

Ahdhemar’s medals and records did not come about by chance or luck. He overcame a lack of experience and every type of adversity one could imagine through extensive training and study. The Brazilian automotive industry was also not born through a miracle or a simple gathering of signatures on a piece of paper. The effort involved was tremendous and Herculean in nature.

During the era of the Adhemar’s first gold medal – 1952 in Helsinki, Finland – Brazil simply did not produce vehicles. 100% of the vehicles in Brazil were imported. A few companies such as Ford and General Motors merely assembled some of their vehicle models in Brazil, bringing practically all of the parts in from overseas – the nationalization index by weight (the manner in which it was measured at the time) was extremely low, less than 20%.

Brazil was stagnant, and one of the reasons was the tremendous lack of transportation, both for people and cargo, whether carried out by road, railway, or along one of the nation’s waterways. A type of dilemma emerged in which economic development did not occur since there was a lack of transportation, but, at the same time, transportation was not available due to the lack of economic development. As a result, expansion of Brazil’s economy and transportation in the country moved at an alarmingly slow pace.

In an attempt to reverse this situation, some important pioneering initiatives were implemented, such as the creation of the Companhia Siderúrgica Nacional (‘National Steel Company’, or CSN) and Fábrica Nacional de Motores (National Engine Factory, or FNM), which assembled trucks that soon came to be known as “FêNêMê”, as well as the founding of Associação Profissional da Indústria de Peças para Automóveis e Similares (the Professional Association of Auto Parts and Similar Industries), later known as Sindipeças, in 1951 and Associação Profissional dos Fabricantes de Tratores, Caminhões, Automóveis e Veículos Similares (Professional Association of Manufacturers of Tractors, Trucks, Automobile, and Similar Vehicles), which came to be known as Sinfavea, in 1955.

But do not come to the conclusion just yet that the Brazilian automotive industry was introduced unanimously. This was actually in fact far from the case. A strong misconception was responsible for every type of barrier against development of the nation’s automotive industry. People believed that Brazil had what was essentially an agriculture-based economy that exported raw materials and imported manufactured goods. It was also argued that our iron ore was of a poor quality, that it was not possible to cast an engine block in a country with a tropical climate such as Brazil.

But pioneers of the automotive industry in Brazil did not take heed to this brand of defeatism. Backed by measures implemented by presidents Getúlio Vargas and Juscelino Kubitscheck, the Brazilian vehicle industry officially came into being on the 16th of June 1956, one month after ANFAVEA was formed, with the creation of Grupo Executivo da Indústria Automobilística (the Executive Group for the Automobile Industry, or GEIA), which instituted legislation that made the development of automotive industry in Brazil feasible.

The result was impressive; by 1960, less than a decade, Brazil had established 250 auto parts factories and three assembly plants for 1200 auto parts manufacturers and eleven vehicle manufacturers. The nationalization index by parts weight that year grew by an outstanding 90% for trucks and 95% for jeeps and automobiles.

Critics, however, did not acknowledge these advancements and came to describe the national automotive industry in Brazil as a “farce”. They searched for any excuse that they could find. First, they alleged that the stimuluses provided by the government were damaging. However, the exemptions on tariffs and taxes provided by the Brazilian government did not affect federal coffers since they did not include these amounts in the budget, since the automotive industry in Brazil did not yet technically exist and these resources therefore also never existed. Additionally, the GEIA for its part required serious and strict obligations with pre-established deadlines and production volumes that were met at the risk of companies.

Afterwards they stated that there would not be enough buyers for vehicles manufactured here in Brazil (“The plan was too ambitious”, they claimed). Later they would allege that the quality of national products was doubtful at best. They therefore concluded that imported products were cheaper than those made in Brazil, which were taxed at more than 50%. Critics even suggested that the automotive industry was responsible for increasing inflation, since they paid better wages and used a great deal of local materials.

The political climate was tense, and the nation was divided. The still young Brazilian automotive industry needed to that it was indeed serious and that it had arrived in Brazil not for adventure’s sake, but rather to help move development in the country forward. And it proved its worth: by 1964 it had already reached the almost unbelievable mark of 1 million vehicles produced nationally, leaving skeptics stunned.

After finally being consolidated, the Brazilian automotive industry did not stop growing. By 1966, Brazil was already the world’s second-largest vehicle manufacturer, and the percentage of nationally developed models in its total fleet surpassed 60%. We reached the mark of a half a million vehicles produced per year in 1971, and a million per year just seven years later, in 1978. Proving the quality of cars manufactured in Brazil, during this same time period we reached a total volume of 500 thousand vehicles exported.

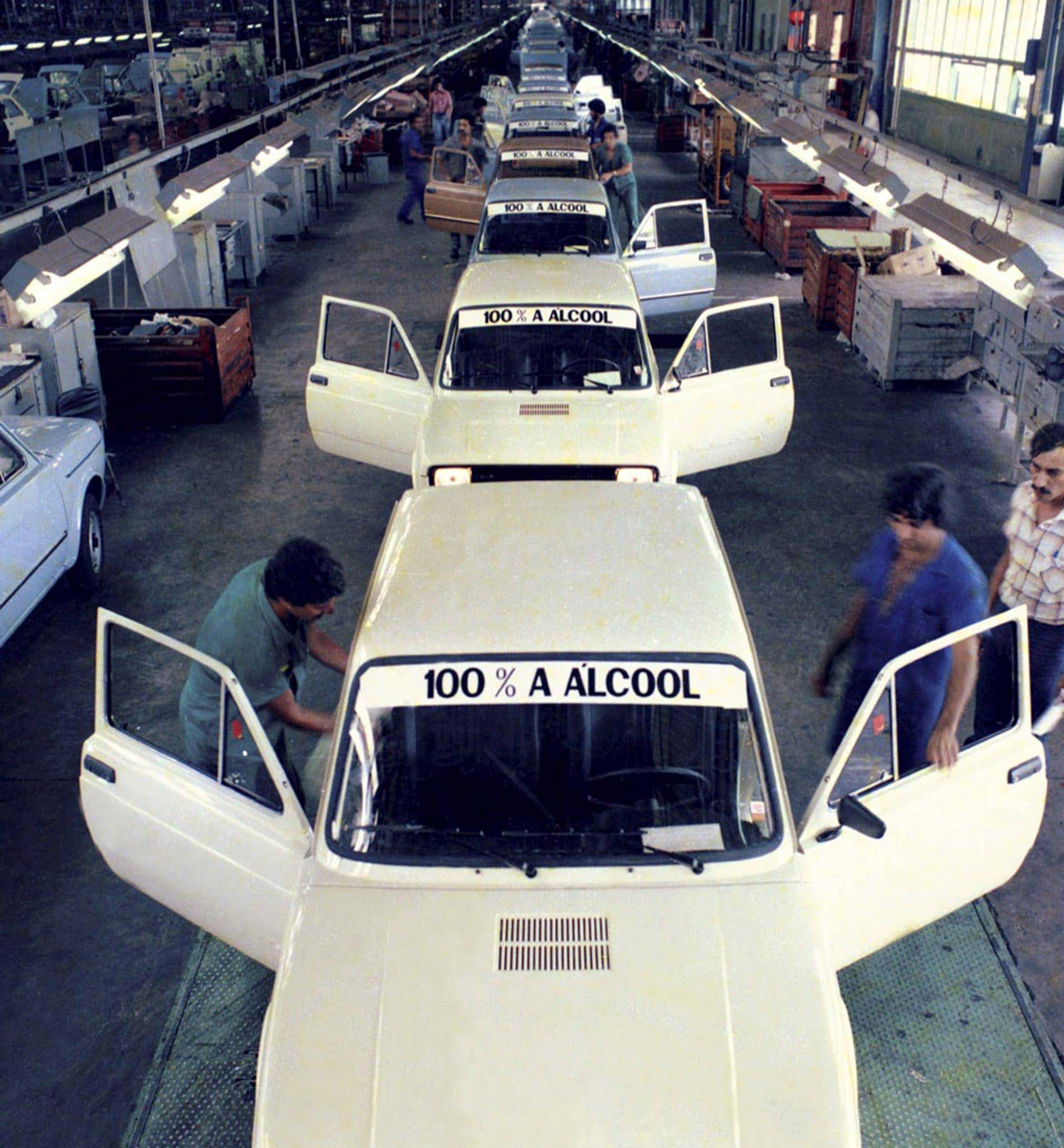

The world at the time was in the middle of an oil crisis, which severely affected our balance of trade and therefore the economy. The national vehicle manufacturing industry once again came up with a solution: in 1979 it introduced the ethanol-powered vehicle, an exclusively Brazilian technology and proof of the technical capacity and inventiveness of our engineering.

Ethanol-powered vehicles had an immediate impact. By 1983, ethanol-powered vehicles already totaled 99.5% of total vehicle sales, and 1989 saw an accumulated production of 20 million vehicles in Brazil.

The arrival of the 1990s brought with it great technological advances such as cellular phones and Internet, as well as the reopening of Brazilian ports to imported products. A sense of modernity emerged and, in partnership with workers, auto parts manufacturers, dealerships, governments, and different organs, what were known as sectoral automotive agreements were created in 1992, 1993, and 1995 that, among other acts, established the standard passenger vehicle (‘popular’ car, or ‘carro popular’), which was fundamental to increasing market numbers and production.

At the start of the new millennium, the national vehicle industry once again proved itself to be an example for the rest of the world with the development of flex-fuel technology. To date, more than 30 million vehicles manufactured in Brazil have been equipped with the technology. Flex-fuel allows vehicles to operate on any combination of ethanol and gasoline.

In 2012, Brazil instituted Inovar-Auto, a national automotive industrial policy regime, which was to remain in effect for five years. Nationally produced vehicles were to become more modern, economic, and safer, as well as less polluting.

From its establishment in 1956 up until today, the Brazilian automotive industry has reached some major milestones. More than 80 million vehicles have already been manufactured, with 17 million of them already exported to more than one hundred countries, in addition to 3 million agricultural machines. There are more than 60 manufacturing plants in Brazil, and around 1.3 million people employed directly by the automotive industry. There are more than 5 thousand dealerships across Brazil. We are the world’s ninth-largest producer and the seventh-largest domestic market. These numbers make Brazil the envy of practically every other country in the world.

In this new decade, the automotive industry in Brazil is undergoing major transformations in the way in which it uses and produces vehicles. This is an essential new phase for Brazil’s automotive industry and is based in Rota 2030 (‘Route 2030’). Rota 2030 is a strategic development program that seeks to make technological advances through research and development carried out here in Brazil by Brazilian engineers and researchers. The tragic events of the Covid-19 pandemic intensified the challenges which were already being faced by not only manufacturers, but the entire automotive supply chain, such as reducing the Brazil Cost in order to provide our products with competitive access to important global markets.

Photos: Miau Collection